|

Handson WingYiu Plastic Metal (H.K.) LTD |

|

|||

Products CategoryContact Us

Tel: +86-755-26515460 |

Mold design

HANDSON provide custom Mould Design and Tooling for Plastic Molding for both local and export market. Capability: - 20 engineers - Product design review - Mould design in 2D and 3D - CAD in Pro-E, Solidwork and Powermill s/w. - Usually we finish mold design in 5 workdays. Mould processing The tooling shop occupies a total area of 2000 square metres, making plastic injection moulds, with of 65 technicians and workers; except ordinary milling and grinding machines, it is also equipped with 11 CNC machines, which can work on hardened moulds directly. And with the Low Speed Wire Cutting Machine with which we used for precision mould milling. We can fabricate 18 tons weigh mould or 1.5mx1.5m size mould, and use hydraulic and hot runner moulds. Plastic injection 850 square metre area equipped with 26 injection machines, size from 55 to 1000 tonnes. Our plastic workshop operate 24 hrs round the clock. Our dayly output is about 350k pcs. Also our in different fields customer products let us to make use of a wide range of materials for making housing and small internal parts, Lens, etc. . . Our commonly used materials like: ABS, HIPS, GPPS, PC, Blended PC & ABS and PMMA, we have also thorough experience in many other engineering materials - ABS (Chi Mei Polylac, GE Cycolac) - HIPS / GPPS - PC (GE Lexan, Dow Calibre, Bayer Makrolon) - PC + ABS (GE Cycoloy, Bayer Bayblend, Kotec) - PMMA (Elf Atochem Oroglas, Mitsubishi) - ASA (Bayer Luran)PA + Glass Fibre (BASF Ultramid, GE Gelon) - PA + ABS (Bayer Triax) - PBT (GE Valox) - POM (Ticona Celcon / Hostaform, Dupont Derlin) - PP (Chisso, Topliene) - PPO (GE Noryl) - PPS (Philips) - SAN (Bayer Lustran) Secondary processing To provide one-stop services, we invested in decorating and assembly facilities as well. which occupies about 850 square metres, and including: - Spraying (including UV painting, a manual spraying line and an automatic spraying line) - Silkscreen-printing - Tampo printing - Hot stamping Product assembly With three product assembly lines. Test center We can provide full-scale product inspection report (CMM report). |

Home

|

About Us

|

Products & Services

|

Manufacturing Facility

|

Equipment List

|

Feedback

|

Contact Us

|

SiteMap

Copyright © 2025 Handson WingYiu Plastic Metal (H.K.) LTD All Rights Reserved

Copyright © 2025 Handson WingYiu Plastic Metal (H.K.) LTD All Rights Reserved

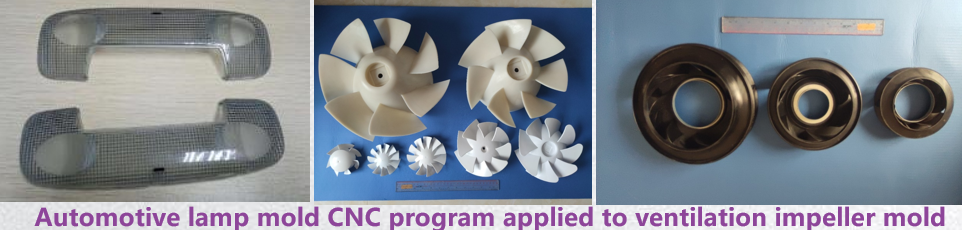

Ventilation System Product

Ventilation System Product